- Phone: +90 (212) 486 18 80

- E-Mail: info@armilla.com.tr

HOW DO WE DO?

HOW DO WE DO?

In the design and static analysis of the projects, we use special programs and auxiliary CAD programs developed for suspended-stretch membrane systems.

Thanks to these superior softwares, we analyze all the loads (pre-tensioning, wind, snow, earthquake etc.) that the structure will be exposed to in local specifications and make static calculations.

We analyze the data, remove the cutting patterns in the computer environment, and proceed to production with precision.

Membrane and carrier elements are fabricated by ARMILLA employees. Membrane parts are perfectly welded by a high frequency welding machine (HF) which does not allow labor defects and provides a clean and correct combination. The management and management of the project is carried out by our expert architects and engineers, & timely error-free &. principles.

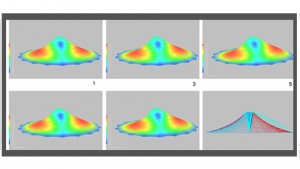

Our architectural project group provides our customers with detailed analysis reports on the 3D form alternatives of the suspended-tension membrane system and their advantages and disadvantages in terms of space, aesthetics and economy.

Form in membrane structures is highly related to structure-load distribution. The building form greatly affects the carrying capacity of the building. Load-elongation relationships are non-linear. The static analysis of the structure is repeated according to each displacement condition. 3-dimensional curl of the membrane to maintain stability under various loads and & lt; / RTI & gt; force must be applied. The amount of pre-stretching is calculated by considering the loads that will affect the & nbsp; membrane in the process of use. Calculation of the pre-tensioning force below normal is the structure; and, if it is considered to be higher than normal, results in the use of a heavy and expensive carrier structure. Membrane; the structure is not only a cover but also serves as a carrier element.

In the design and static analysis of the projects, we use special & nbsp; programs and auxiliary CAD programs developed for suspended-tension membrane systems. Thanks to these superior software, we analyze all structural loads (pre-tensioning, wind, snow, earthquake, etc.) & nbsp; which are determined by local specifications.

Loads obtained from the static-structural structure of the suspended-tension structure on the carriers; For vertical and horizontal carriers, steel-reinforced concrete projects, detail layouts and assembly diagrams are created.

Manufacture

Manufacture

The fabrication of the membrane system is carried out meticulously by ARMİLLA employees.

Membrane parts do not allow labor defects; It is perfectly welded by a high frequency welding machine (HF), which ensures a clean, homogeneous, strong and accurate combination. The system is assembled & nbsp; and the steel ropes are packed and shipped to the site for installation.

The management and management of the project is carried out by our expert architects and engineers, konusunda on time and nbsp error-free r. principles.

Montage

Unlike conventional construction methods, the assembly is completed by the vertical and horizontal attachment of the next element & nbsp;. they reach the required stiffness after the pretensioning is applied to the & nbsp; surface & nbsp; elements. Ensuring the pre-stretching & nbsp; amounts determined during the project phase is of great importance for the life of the building. The method of assembly of the membrane structure is highly correlated with the production quality of the material to be used, the original desired form, and most importantly the details of the membrane & nbsp; joining with other building elements. The correct & nbsp; installation and selection of the assembly method provides great potential in optimizing the construction process. Installation of membrane systems is far beyond the installation of the crane and the installation of the system; It is the right fiction, the right production, the right material, the right stretching techniques, and finally the right inspection, shaped in the design and production process of the material.